BACKGROUND

Chitobiose is a disaccharide with high potential for industrial and commercial applications. The most efficient way to produce chitobiose is through the enzymatic degradation of chitin, a polymer derived from insect and crustacean exoskeletons like shrimp and lobster. Annually, over 1 billion tons of chitin are produced, making it an inexpensive and readily available starting material.

The challenge, however, is that chitin and its widely used derivative, chitosan, can be insoluble and not easily subjected to chemical decomposition to selectively produce specific, high-purity, chito-oligosaccharides (COS) such as chitobiose. COS are more soluble and less viscous than chitosan, which is commercially valuable and used for diverse applications in biotechnology, pharmaceuticals and agriculture. However, producing high-quality COS materials is complex and expensive, costing thousands of dollars per gram. This high cost has likely hindered its broader adoption in these fields and other applications. Therefore, developing methods to produce less expensive, high-quality chitobiose would be highly valuable.

TECHNOLOGY

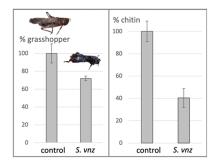

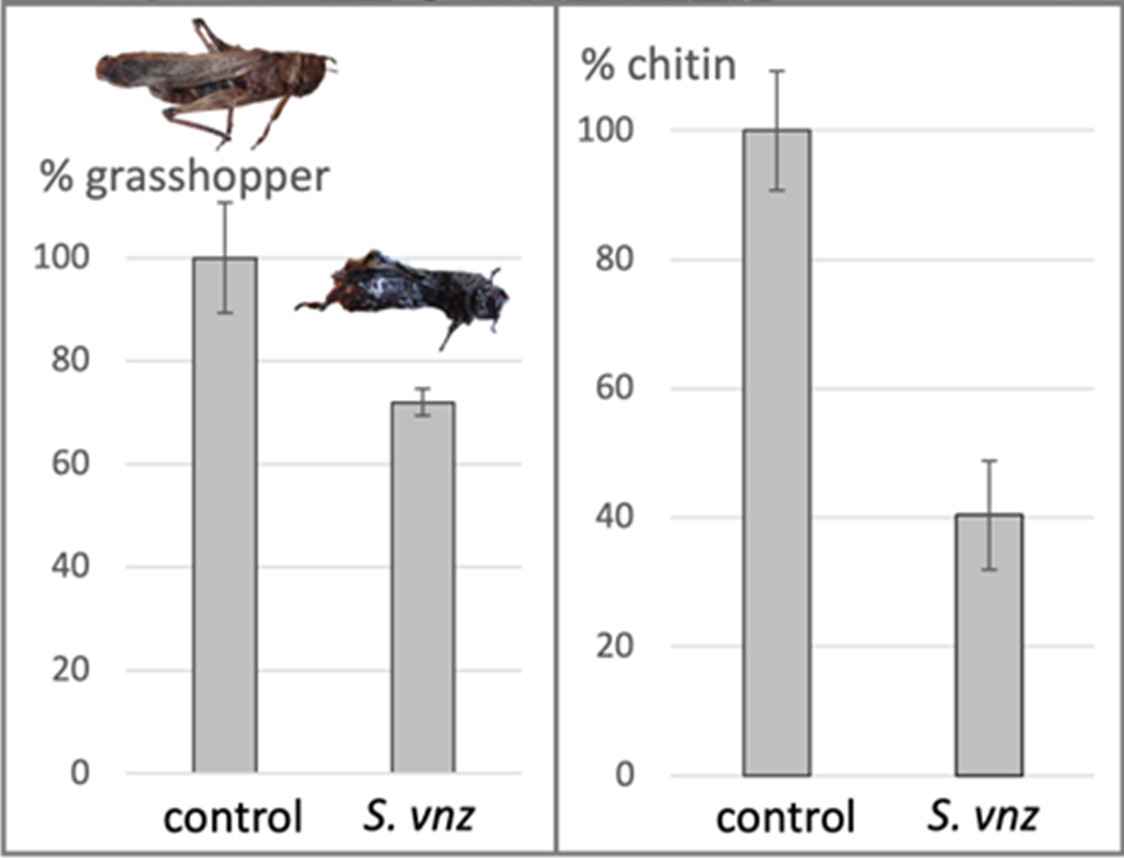

Researchers at the University of Toronto have developed a cost-effective method for producing chitobiose using genetically modified bacteria. They have used Streptomyces venezuelae, which possesses several secretable chitinolytic enzymes, to extracellularly convert chitin to chitobiose (Figure 1). Key to the invention is the knockout of genes involved in the catabolism of chitin, which severely impairs the ability of the bacterium to import the chitobiose into the cell, leaving the metabolite available for harvesting from the highly enriched culture media.

Figure 1. Degradation of insect exoskeleton (left) and chitin (right) by Streptomyces venezuelae (S. vnz). Insect biomass reduced by 27% and chitin biomass by over 50%.

COMPETITIVE ADVANTAGE

- Inexpensive production of chitobiose

- Suitable for scale-up using microbial fermentation

- Avoids use of environmentally damaging and hazardous chemicals

APPLICATIONS

- Production of purified chitobiose and potentially other short chito-oligomers

- Investigating uses of purified chitobiose for various applications

INTELLECTUAL PROPERTY STATUS

- Provisional patent filed (Feb 2025)

PROJECT STATUS

Proof-of-concepts studies are being conducted for production of chitobiose in the laboratory at high gram scale. With the material being readily available and at low cost, the laboratory is investigating various uses of chitobiose.