BACKGROUND

Biological barrier models are essential tools for replicating and studying the selective transport functions of tissues such as the blood-brain barrier, intestinal epithelium, and pulmonary alveolar membrane. These barriers are composed of tightly connected cell layers supported by porous substrates, and they regulate the passage of ions, nutrients, and therapeutic agents while maintaining compartmental integrity. In vitro models of these barriers are widely used in drug development, toxicology, and disease research to assess permeability and barrier function. Porous cell culture inserts, such as Transwell systems, are the most common in vitro model of biological barriers in which endothelial or epithelial barrier cells are grown on a permeable membrane. Transepithelial/endothelial electrical resistance (TEER) is the gold standard technique for assessing the integrity of barrier models, but has a few limitations. Electrical cell-substrate impedance sensing (ECIS) is an alternative to TEER but electrode printing strategies on permeable membranes are impractical for large scale commercial manufacture necessitating new techniques.

TECHNOLOGY

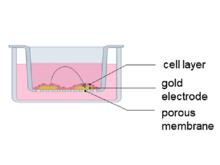

This invention describes a novel method for manufacturing electrodes used in ECIS, specifically designed for integration into porous membrane-based cell culture systems. The process involves heat-bonding a biocompatible, electrically conductive sheet—preferably gold or a gold alloy—directly onto a porous membrane, forming a laminate with conductive and permeable surfaces (Figure 1). Electrode components are then precisely patterned using photolithography techniques, enabling the creation of embedded electrodes without relying on complex or commercially impractical printing strategies. This manufacturing approach allows for scalable, reproducible production of ECIS-compatible membranes, which can then be used to monitor barrier integrity in real time. The resulting platform supports dynamic biological barrier modeling and is compatible with a wide range of cell types and experimental setups.

Figure 1. Fabrication and assembly of well plate insert ECIS membrane electrode devices. The fabrication process involves thermal bonding of a gold leaf to a porous membrane, followed by electrode patterning using UV lithography. The resulting membrane electrodes are integrated into a standard cell culture insert format. The schematic on the right illustrates current flow between ECIS electrodes through the endothelial cell layer and surrounding culture medium.

COMPETITIVE ADVANTAGE

- Scalable Electrode Fabrication: Avoids complex printing techniques, enabling cost-effective mass production.

- Integrated ECIS Capability: Facilitates real-time, non-invasive monitoring of barrier integrity.

- Biocompatible and Versatile: Compatible with a wide range of cell types and barrier models.

- High-throughput screening platform

APPLICATIONS

- Drug permeability and transport studies

- Disease modeling of barrier dysfunction

- Toxicology and safety screening

INTELLECTUAL PROPERTY STATUS

- US, CA Applications (June 2023 priority)

PROJECT STATUS

Electrode-integrated membranes have been fabricated and tested with barrier-forming cell lines. Preliminary results demonstrate reliable impedance measurements and compatibility with standard cell culture workflows.

KEYWORDS

- biological barriers, ECIS, TEER, porous membrane, impedance sensing, cell culture, permeability, drug transport, organ-on-a-chip, electrode fabrication