Printed electronics is a growing $18B market, but materials innovation has not kept pace with demand. Current inks are dominated by costly, high-conductivity metal inks (e.g., silver, copper) and inexpensive but low-performance carbon inks. PEDOT:PSS, a widely used conductive polymer in research, offers a middle ground with unique advantages—yet has never been commercialized for printed electronics due to challenges in formulating high-concentration, printable hydrogels.

This technology introduces the first commercially viable hydrogel ink for printed electronics. This sustainable alternative balances conductivity, cost, and environmental impact to serve emerging applications in wearables and medical sensors.

TECHNOLOGY

A first-of-its-kind, process and conductive polymer (CP) hydrogel ink with extended shelf life, tailored printability, and high conductivity—unlocking 2D and 3D printed electronics. Gaps in flexibility and performance for wearable tech and other applications that required flexible electronics are mitigated through a novel synthesis method using super-absorbent polymer (SAP) beads to concentrate PEDOT:PSS into a printable hydrogel (1–10 wt%) without crosslinking. This room-temperature, waste-free process enables scalable, cost-effective production of PEDOT:PSS ink suitable for multiple printing techniques.

Key Features:

- Sustainable Production: Near-zero energy, reusable SAP beads, and no toxic byproducts.

- Price/Performance Balance: Priced near carbon ink but 100x more conductive; 1/10 the cost of silver ink with a fraction of the CO2 footprint.

- Versatile Compatibility: Printable via screen printing, inkjet, DIW, and extrusion.

- Environmentally Superior: Lifecycle CO2 emissions 90x lower than silver ink.

BENEFITS

- Extended Shelf Life: Improved storage stability compared to conventional CP inks.

- 3D Compatibility: Supports additive manufacturing of complex, layered, or volumetric structures.

- Energy & Cost Efficient: Near-zero energy synthesis reduces environmental and economic burden.

- High Responsiveness: Maintains functional conductivity under mechanical deformation.

APPLICATIONS

- Wearable and Flexible Electronics (e.g., smart textiles, e-skin)

- Printed Energy Storage (e.g., micro-supercapacitors for wearables)

- Medical Devices (e.g., biosensors, soft robotics)

- Printed Circuitry on flexible or biocompatible substrates

OPPORTUNITY

- Printed & Flexible Electronics: $18B (2023) → $40B+ by 2030 (IDTechEx, 2023)

- Wearable Electronics: $70B by 2028 (MarketsandMarkets, 2023)

- Energy Storage in Wearables: $4.5B by 2027 (Precedence Research, 2023)

STATUS

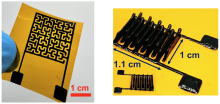

- TRL 3: Currently printing 2D and 3D flexible electronics (sensors and electrodes) for biomedical applications. Developing the ink and nanoparticles mixture and optimizing the printing properties

- US and Canadian patent applications filed July 2025 covering hydrogel synthesis workflow, formulation for rheological control, and functional printed device architecture

- Seeking partners for licensing and pilot testing